Fillet Weld Design for Skewed Shear Tabs Flow Chart 5 16 t p ½ 0 θ 45 Table 10-14C 14th Ed. B Corner joint fillet weld.

Other welds include partial penetration groove welds.

. Eurocode 1993-1-82005 gives a designer a choice between two methods for the design of fillet welds. Per the D11 the equivalent leg size would be 123 x 019 0234 w. 62 Design of Welded Connections Fillet welds are most common and used in all structures.

The following table is in accord with data in BS 5950 part 1. Increments A fillet weld can be loaded in any direction in shear compression or tension. Oenoral Construction Specification O-29C has been revised to clarity.

Skewed T-joint fillet welds have either been qualified by analysis andor testing or are considered nonload carrying welds. In order to weld the full thickness of a plate and achieve the weld throat thickness required by design it is therefore necessary to cut away sufficient metal along the joint line so that the welding electrode has access to the root of the joint enabling the root pass to be deposited and then the remainder filled to complete the joint. Strength equivalent to a 90 degree 316 inch fillet weld.

View design_file102pdf from CE 155 at University of the Philippines Diliman. X 200 mm. In the directional method the force acting on the fillet weld is resolved into components parallel and.

24 Fillet Welds 241 Effective Throat 2411 Calculation. Single-sided fillet welded joint types. Other references For those who are interested in actually designing welds the following is a useful simple guide.

The fillet weld capacity tables related to the type of loading on the weld. Designing Fillet Welds for Skewed T-Joints Part 1 Lessons Learned in the Field. Engineers and designers have been alerted to the AISCAWS requirements for limiting angles for skewed T-joints.

Fillet welds are probably the most common type of weld particularly in structural steel work applications so this first section will look at some of the design considerations of fillet welds. Butt Weld 12 Transverse Fillet 15 Parallel Fillet 27 T-butt with corners 20. For angles between 60 and 80 degrees the designer has to account for the effective throat using the formula contained in Annex B D11.

A weld preparation the weld prep is therefore. Depending on the skewed t. Types of joint preparation.

If the dihedral angle is less than 80 or more than 100 degrees it is a welded skewed T-joint. The skewed T-Joint angle is 120 degrees psi symbol zero root opening. Detailing fillet welds for 90-degree T-joints is a fairly straightforward activityTake the 90-degree T-joint and skew itthat is rotate the upright member so as to create an acute and obtuse orientation and the resultant geometry of the fillet welds becomes more complicated see Figure 1The greater the degree of rotation the greater the differ-.

The American Welding Society Structural Welding Code - Steel AWS D11 provides design and detailing requirements for skewed t-joints. No reduction shall be assumed in design calculations to allow for the start or stop of the weld. 2337 Effective Throat of Skewed T-Joints.

Fillet Weld Strength Design Calculation in Torsion Example. IPlace welds near the neutral axis of the part. Based on design strengths as shown in.

C Lap joint fillet weld. Fillet welds are probably the most common type of weld particularly in structural steelwork applications so this first section will look at some of the design considerations of fillet welds. A series of equations can be used to.

However many designers are unaware of the AWS D11 skewed t-joint requirements and apply typical 90. If the dihedral angle is less than 80 or more than 100 degrees it is a welded skewed T-joint. A T-joint fillet weld.

They may be used to make T lap and corner joints Fig4. See Annex II for formula governing the calculation of effective throats for fillet welds in skewed T-joints. AiSC Manual Skewed Shear Tab Fillet Welds aiSC 360-10 aWS D11D11M2010 1 2 θ 10 Provide Fillet Weld leg Size Clause 234 aWS a 10 θ 60 Provide Effective Throat area Clause 234 aWS B 60 θ.

Depending on the skewed t-joint geometry designers are required to define the required weld leg or effective throat size. The effective throat shall be the shortest distance from the joint root to the weld face of the diagrammatic weld see Annex I. The effective throat of a skewed T-joint in angles between 60 and 30 shall be the minimum distance from the root to the diagrammatic face.

The term fillet weld is applicable to welds deposited on the joint with dihedral angles between 80 and 100 degrees. The simplified and the directional methods. They may be used to make T lap and corner joints Fig4.

2336 Minimum Skewed T-Joint Weld Size. 2 Factors in Weld Design IStrength static andor fatigue IMaterial and the effects of heating ICost. The fillet weld design clauses in AISC 360 Section J24a permit the use of a so-called directional strength enhancement factor for fillet welds ie.

The weld loading should be such that F L P L 2 F T P T 2 1. Part 12013 Manual metal-arc welding gas-shielded metal-arc welding gas weld-ing TIG welding and beam welding of steels. The requirements of 2328 shall apply.

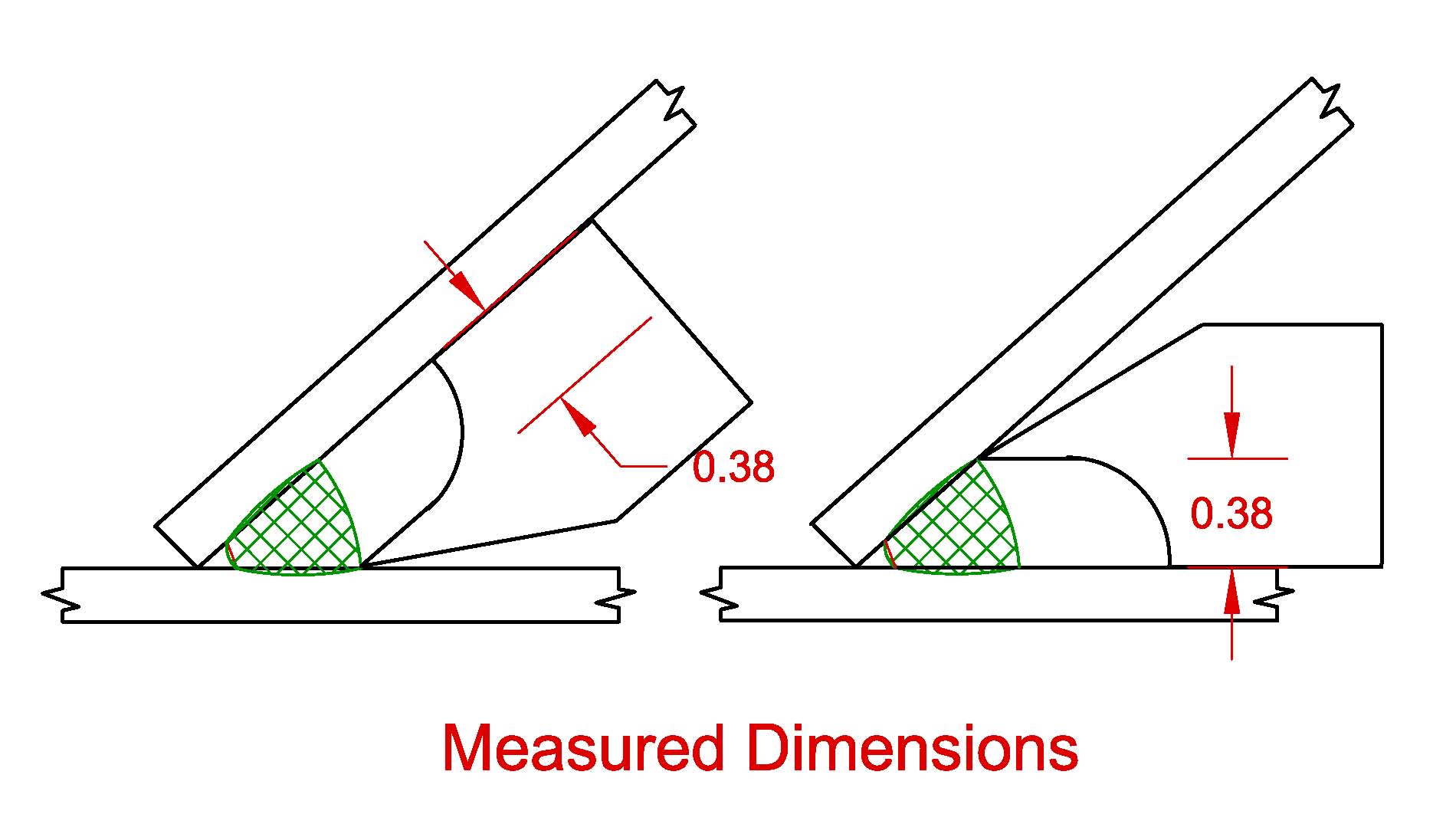

Look at the design of the welded connection below its a cantilever kind of structural joint where the fillet welds are subjected to the torque developed due to the load F. The present invention comprises a gauge for measuring certain dimensions of welds at skewed T joints the gauge being broadly denoted by the numeral 10. Calculate the fillet weld size required for the application.

Fillet weld size shown in Table 10-14C on page 10-177. Typical welds capable of being measured with gauge 10 are welds 12 and 14 shown in FIGS. Consider the Transfer of Stress through Members Welding Innovation Vol.

However it always fails in shear. Two types of loading are identified traverse loading and longitudinal loading as show below. The American Welding Society Structural Welding Code - Steel AWS D11 provides design and detailing requirements for skewed t-joints.

2_PDFsam_Designing Fillet Welds for Skewed T-jointsâ__Part 1 - The James F. Download Citation Designing fillet welds for skewed T-joints - Part 1 Detailing fillet welds for 90-degree T-joints is a straightforward activity. The 100 050sin 15 θ term in Equation J2-5 which enables the weld strength to be enhanced when the direction of loading is non-parallel to the axis of the weld.

There is no specific guidance on which method to use and in practice the choice is usually made on practical grounds. Part 21998 Submerged arc welding of steels. In calculating tn in the D11 tn defined as the distance from the root of the joint to the face of the diagrammatic weld tn w2sinpsi2.

A tabulation of mea-. Given F 20000 N. Weld sizes are specified in 116 in.

The Skew T Fillet Weld Gauge By Gal Gage Company Youtube

Skewed Shear Tab Welding How Sds2 Designs Shear

Skewed T Joints Between 60 And 30 Degrees

![]()

Welding Joints Types Symbols And Pictures Www Materialwelding Com

0 comments

Post a Comment